Swaging process6 merit

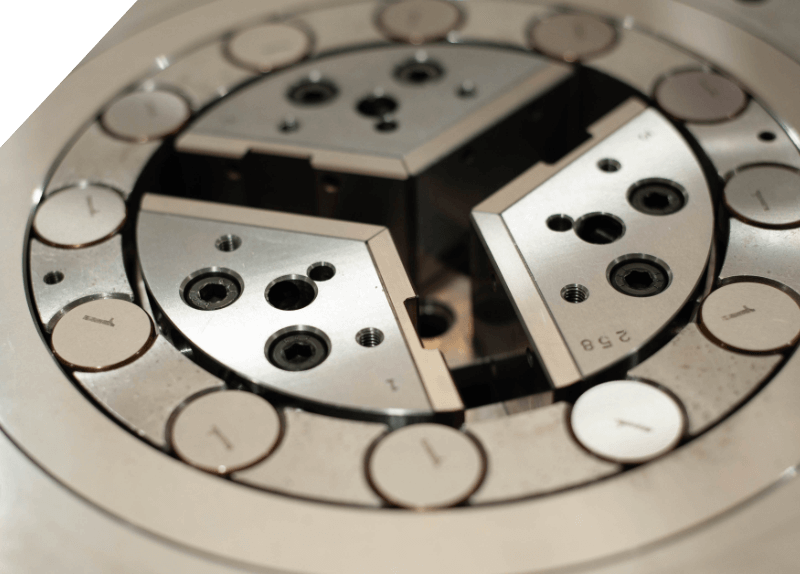

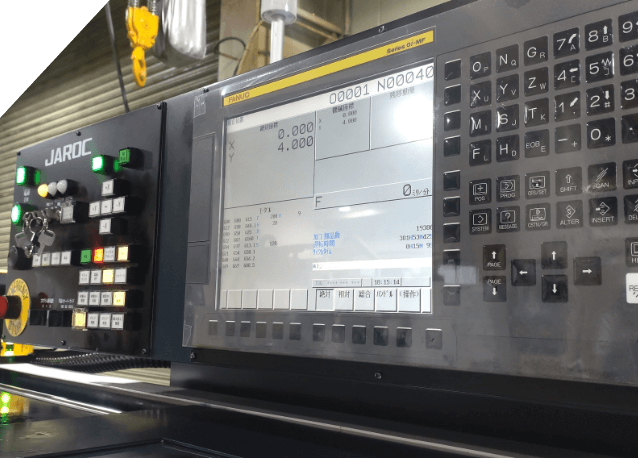

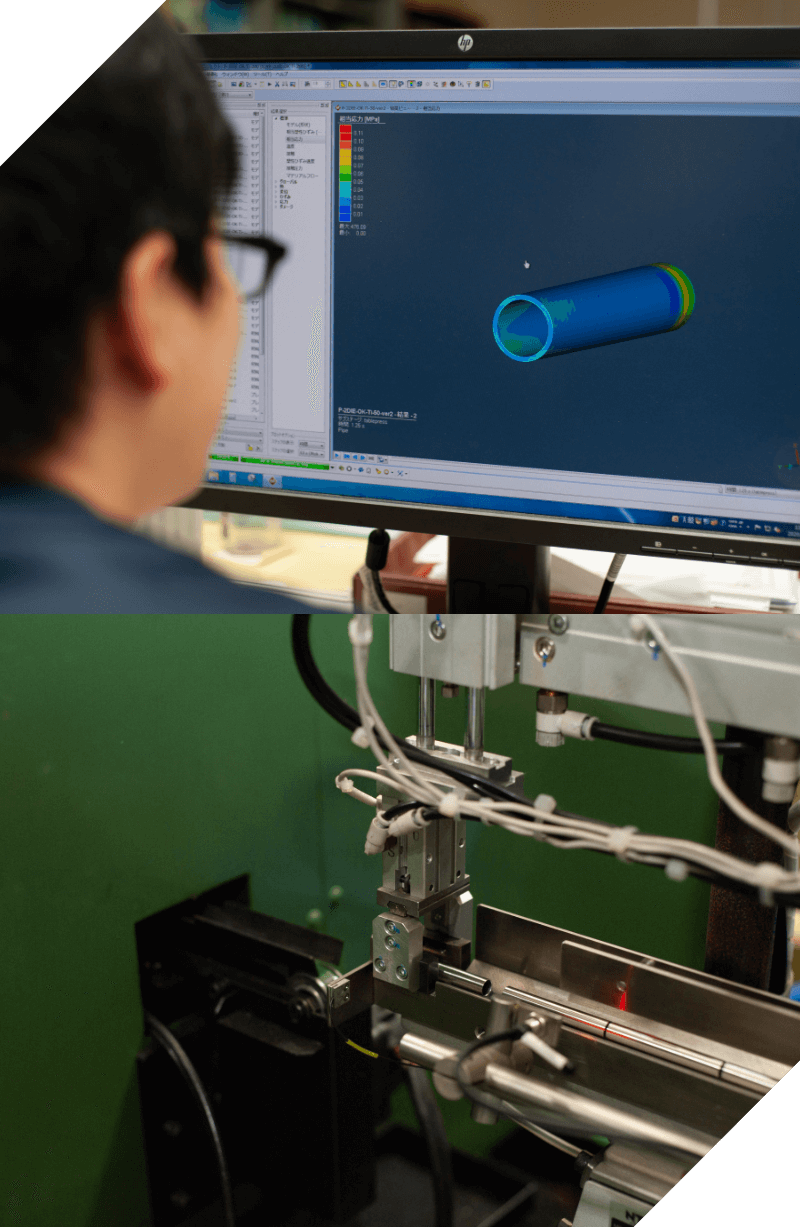

Swaging is cold forging process by plural dies which is rotating around the material pass line to reduce the outer diameter of the pipe and round bar. JAROC offers products with high dimensional accuracy by applying CNC (Computer Numerical Control) technology in which die setup and dimension adjustment is carried out quite easily. For the tube spline, it is possible to create a female-shaped spline shape to the inner diameter by swaging processing in the situation where cored bar of the spline (male type) is put in pipe.

In addition, the mechanical properties (material strength, rigidity, springiness, breaking limit torque, etc.) can be improved by performing cold-swaging process.

Because it is cold forged, it does not cut the material and is chip-free.

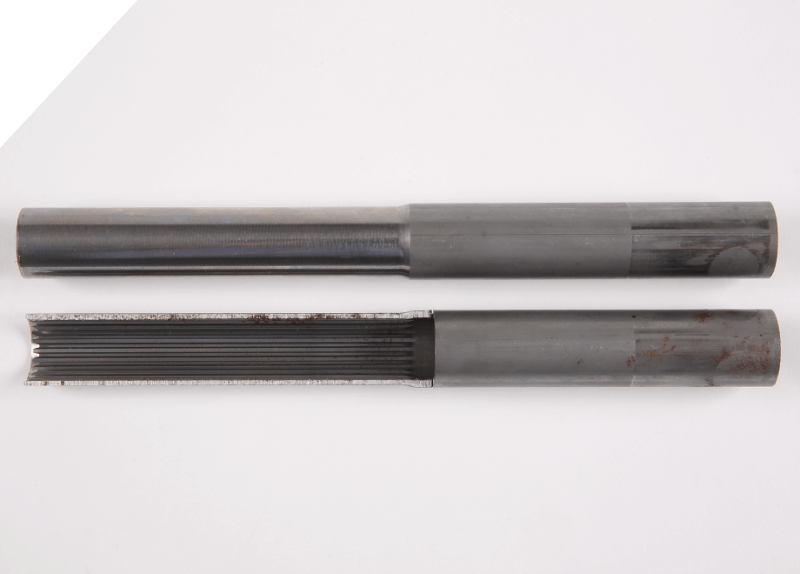

The inner diameter spline shape can be processed by inserting a core metal into the inner diameter processing. The inner wavy accuracy is also enhanced.

Machining with good dimensional accuracy is possible with CNC control.

We can also process Ti, Ti-6Al-4V, β-Ti, Ni-Ti, Al, Sus and Mg.

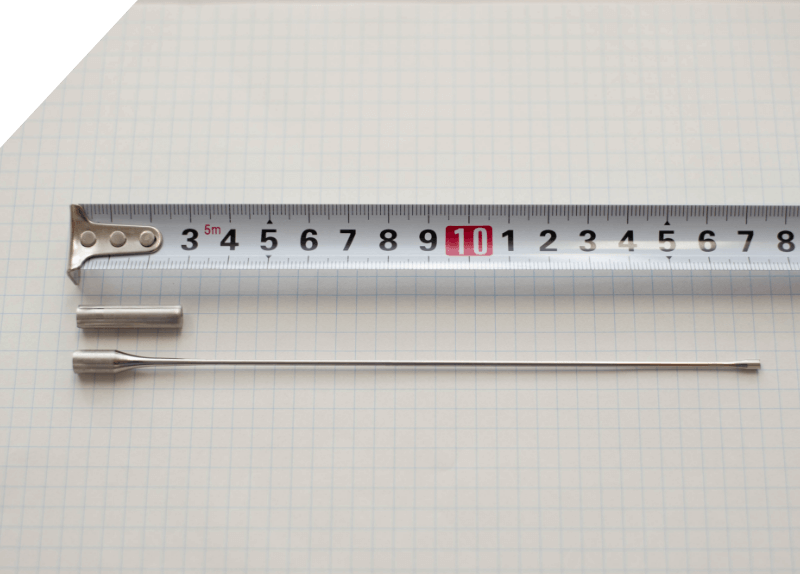

By molding conventional solid material products with hollow materials, we can reduce the weight of parts.

Material costs are reduced because the material is stretched from the shortest material.

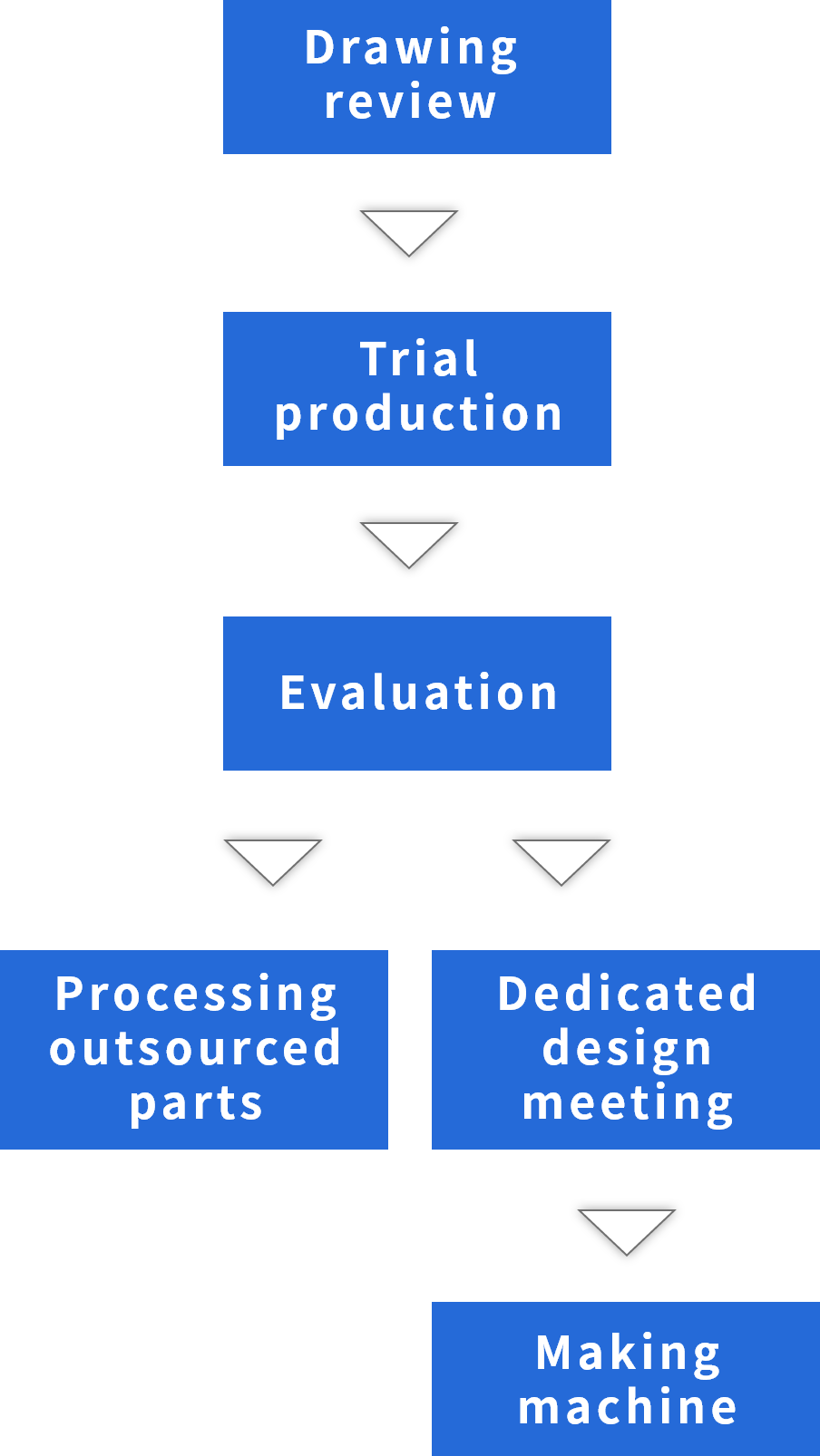

Estimate of prototype machine

"I want to process ◯◯ mm material to ◯◯ mm" "Is this material processable?" Please contact us from the trial production first. The quote is free.

Making machine

We are the first in the world to develop a CNC swaging machine and manufacture a dedicated machine to meet the needs of our customers. We also manufacture swaging dies and plastic working machines.

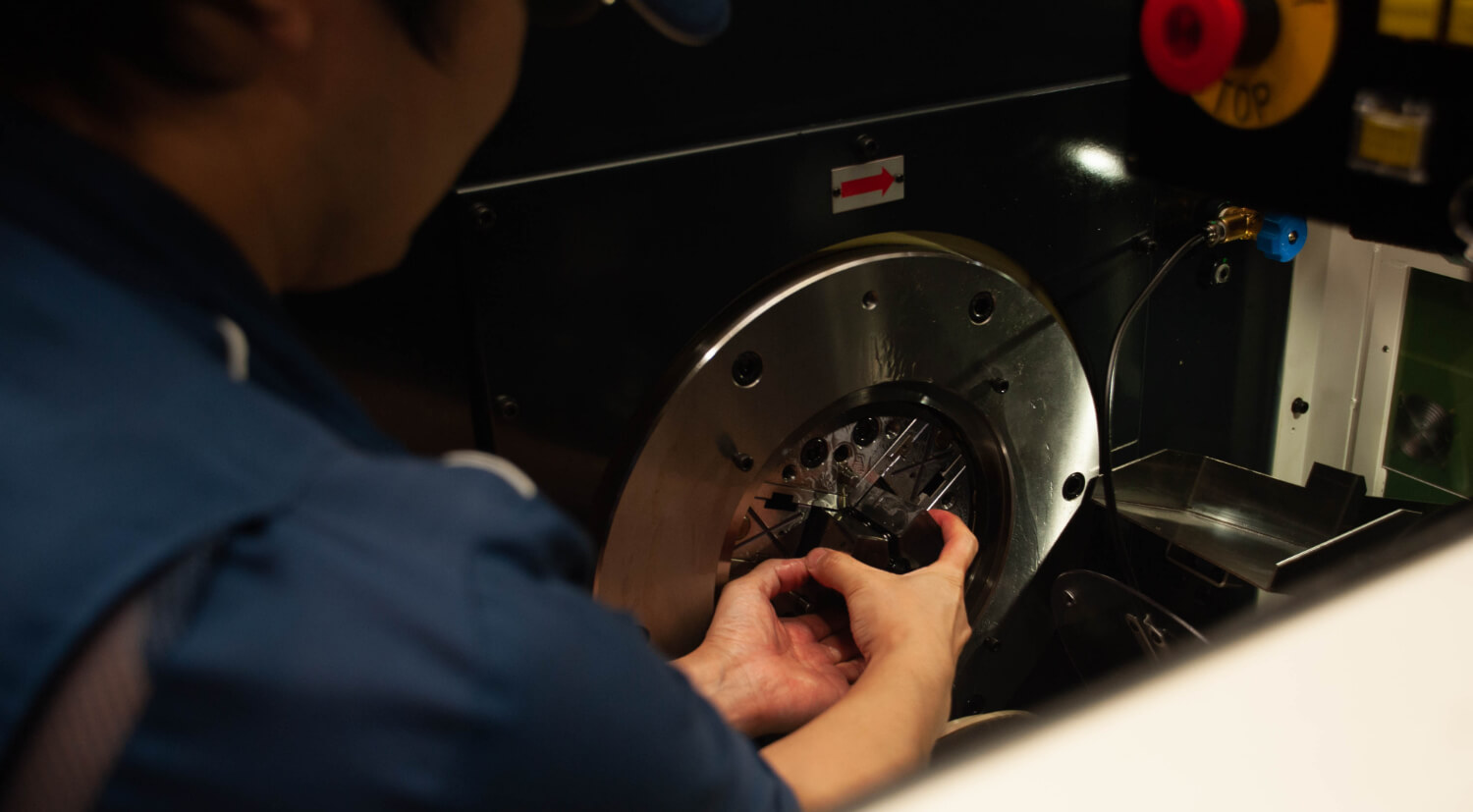

Processing outsourced parts

We are working hard every day to make our products unique and to make our customers happy by utilizing our in-house manufactured swaging machines.

products together!